Nuffield Centre, Portsmouth

Complete solution on-site

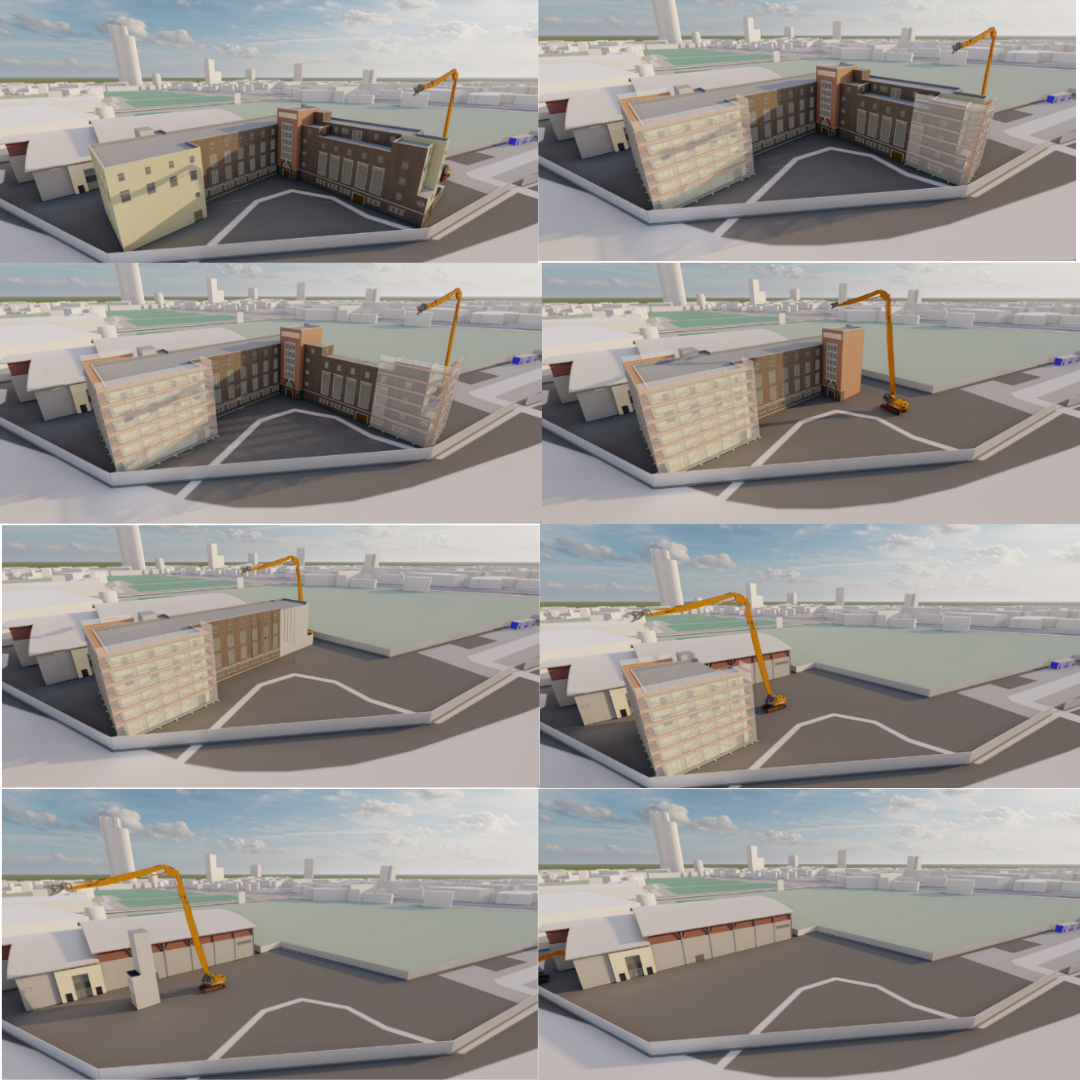

CAD sequencing used during tender and project stages

Social Value Initiatives

Hughes and Salvidge completed the demolition works at Nuffield Centre in Portsmouth on behalf of the University of Portsmouth in mid-2023. The project was tendered including the neighbouring Spinnaker Building. Hughes and Salvidge secured the full project – Nuffield and Spinnaker – with the demolition of the Spinnaker Building scheduled for 2024.

The 15-week project included site set-up, soft-strip of the building, the salvaging of items, asbestos removal works, the structural demolition to slab level, grubbing up of the slabs and foundations, and the crushing of all demolition arisings. The site was located at a busy junction, flanked by two roads taking traffic out-of-city. On opposing sides, was the Student Union for the University of Portsmouth, a nine-storey University building, and a residential block. To the rear of the building was a car park that we were able to include within the site boundary and utilise for welfare and site offices. Adjacent to the car park was the United Services sports ground.

Hughes and Salvidge completed the soft-strip of the building and our in-house Asbestos Removal division, H&S Asbestos, completed the asbestos removal works ahead of structural demolition.

Both the eastern and southern gable ends were scaffolded with protection scaffold fixed to the building and Monarflexed. This was installed prior to demolition taking place and was struck in a sequence as the building came down to ensure there was never more than two lifts unsecured to the building. Unsecured lifts had the Monarflex removed so as not to catch the wind and cause any excess force through either the building or scaffold.

Works commenced from the car park area with the High Reach machine working from the top down, using a selector grab, shear and pulveriser attachments. The building was of masonry construction with a steel frame, in some instances it was coated in re-enforced concrete. The machine operator carefully demolished the building with the arisings being passed to back up machines working behind for processing and smaller arisings being allowed to fall within the footprint of the building. Stair and lift cores were retained for as long as possible acting as strength to the structure during demolition.

Once a significant amount of the ground bearing slab was exposed, machines fitted with impact hammers and buckets removed the slab and foundations. A machine fitted with an impact hammer began by puncturing the slab and foundations breaking them up into moveable sections. A machine fitted with a bucket then lifted and stockpiled sections ready for further processing. Machines fitted with pulverisers processed arisings further to separate concrete from reinforcing bar, and load away respective materials.

All excavations were backfilled progressively after the foundation removal; the area was graded to surrounding site contours, and the footprint tracked in by machine, leaving a flat site.