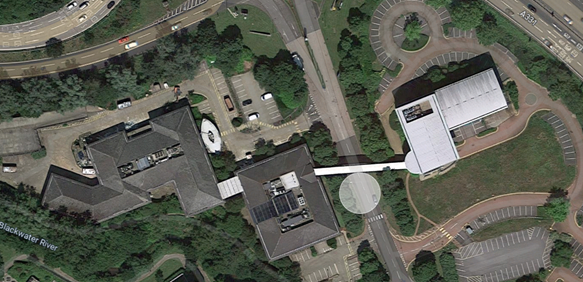

Novartis, Frimley

Hughes & Salvidge were appointed the role of Principal Contractor for Demolition works at the former Novartis Buildings, Frimley Business Park in Camberley.

Outline Scope of Works

- Asbestos Removal to Building 1&2, low risk items putty and gaskets

- Tree removal and tree protection as per Impact Assessment

- Demolition of buildings 1,2 3 and the link bridge

- Disposal of all arising materials

- Breakout of slabs and foundations

- Crushing of all arising materials to site use 6F5

Within buildings one and two, there is the possibility for bats to be present within the roofs. H&SL worked efficiently in conjunction with a bat license and watching brief of the ecologists to complete the works with zero issues.

As works progressed to the western most part of the structures, there was a public footpath and the black water river running behind. Works were more controlled in this area, with marshals on the foot path when demolition is ongoing and the walls all being brought into the footprint of the site away from the footpath and river, ensuring both were free from debris at all times. Works ceased as walkers required access, and resumed once walkers are clear.

Asbestos removal and soft strip

All asbestos removal works were completed prior to any soft strip and structural demolition of buildings. The soft strip phase involved the removal of all fixtures & fittings, furniture, carpet tiles, false ceilings, timber, services, cables, light fittings and insulation/lining boards within the structures to allow for the demolition, and in order to minimise the amount of potential contaminants in the material to be crushed.

Superstructure Demolition

Works commenced on the Western side of the road (buildings 1 & 2) getting the structures down to slab level before commencing onto the opposite side of the road (building 3), while slabs and foundations were being removed on B1 & 2.

The machine fitted with a selector grab attachment, firstly reduced the gable end wall top down to expose the roof and intermediate floors. The roof was then lifted back to the second bay allowing demolition arisings to fall onto the lower intermediate floor. The steel frame was stripped of perimeter brickwork and concrete floors leaving just the steel frame in situ. All walls were folded over into the confines of the building. All window units were removed and lowered to ground floor level for processing. The machine then lifted the intermediate floor planks a bay at a time, leaving the steel columns standing. Once a bay of steel framework had been exposed, the machine proceeded to dismantle the framework. This process was adopted throughout, working the building down a bay at a time.

Throughout the demolition process, smaller machines were employed to carry out processing and loading away of arisings. Once the superstructure had been demolished, machines fitted with breakers will begin to puncture the ground floor slab. A secondary machine fitted with a bucket then lifted and stockpile these arisings, ready for further processing and crushing.

Link Bridge Demolition

Following the demolition of buildings 1, 2 & 3 the link bridge was demolished over a weekend, as agreed with the other estate stakeholders. Prior to demolishing the link-bridge structure, tree protection measures were installed in line with the Arboricultural Method Statement, approved by Surrey Heath District Council.

Timber Ekki matts were brought to site, and upon putting in place a road closure, the Ekki matts were placed out on the road surface and to protect the banks to form a protective matt under the bridge and for plant to run on. The matt stretched approximately 8m either side of the bridge and underneath.

Once in place, 50t excavators worked in tandem with shear and selector attachments to start bringing the bridge down, clipping all of the upper frame works down first before tapping through the concrete deck floor. The last items to be cut were the main floor beams, these were cut by machine with shear while a machine with a selector held it in place.

Substructure Demolition

Once a significant amount of ground bearing slab had been exposed, machines fitted with impact hammers and buckets began to remove the slab and foundations. A machine fitted with an impact hammer started by puncturing the slab and foundations to break them up to moveable sections. A machine fitted with a bucket then lifted and stockpiled sections ready for further processing. Machines fitted with pulverisers processed arisings further to separate concrete from reinforcing bar, and loaded away respective materials.

All excavations were backfilled progressively after foundation removal. The area was graded to surrounding site contours, and the footprint tracked in by machine, leaving a flat site.

Crushing

Site-won hard inert arisings were crushed on site to produce aggregate for re-use.

Works commenced by loading the crusher using a 360° excavator. Concrete/hardcore was loaded into the hopper, which was hydraulically fed into the crusher. The crushed material fell onto the conveyor where any reinforcement bar or other ferrous metal was removed by a hydraulic belt magnet fitted above the main conveyor. The crusher then discharged crushed aggregate and metal into two separate stockpiles. Metal was periodically loaded away into metal bins, and aggregate was regularly cleared and stockpiled in the client’s desired location. Aggregate stockpiles were formed with a suitable angle of repose to ensure they remained stable and to mitigate any land-sliding of aggregate.

The crusher is fitted with a dust suppression system, whereby water is sprayed onto the discharge conveyor to minimise dust. All areas were left clean and tidy on completion.