Our Projects

Hughes and Salvidge possess a wealth of experience delivering diverse successful projects. Explore our ongoing live projects and learn of our past undertakings. No project is alike, we regularly adapt our ways of working to accommodate this and surpass client needs and expectations.

Straddle Carriers, Port of Southampton

Hughes & Salvidge were appointed the role of Principal Contractor for felling of 9 straddle carriers within the Port of Southampton....

Former Gate Gourmet Catering Base, Heathrow Airport

Hughes and Salvidge were appointed by AIPUT as Principal Contractor for the demolition of the Former Gate Gourmet Catering Base at Heathr...

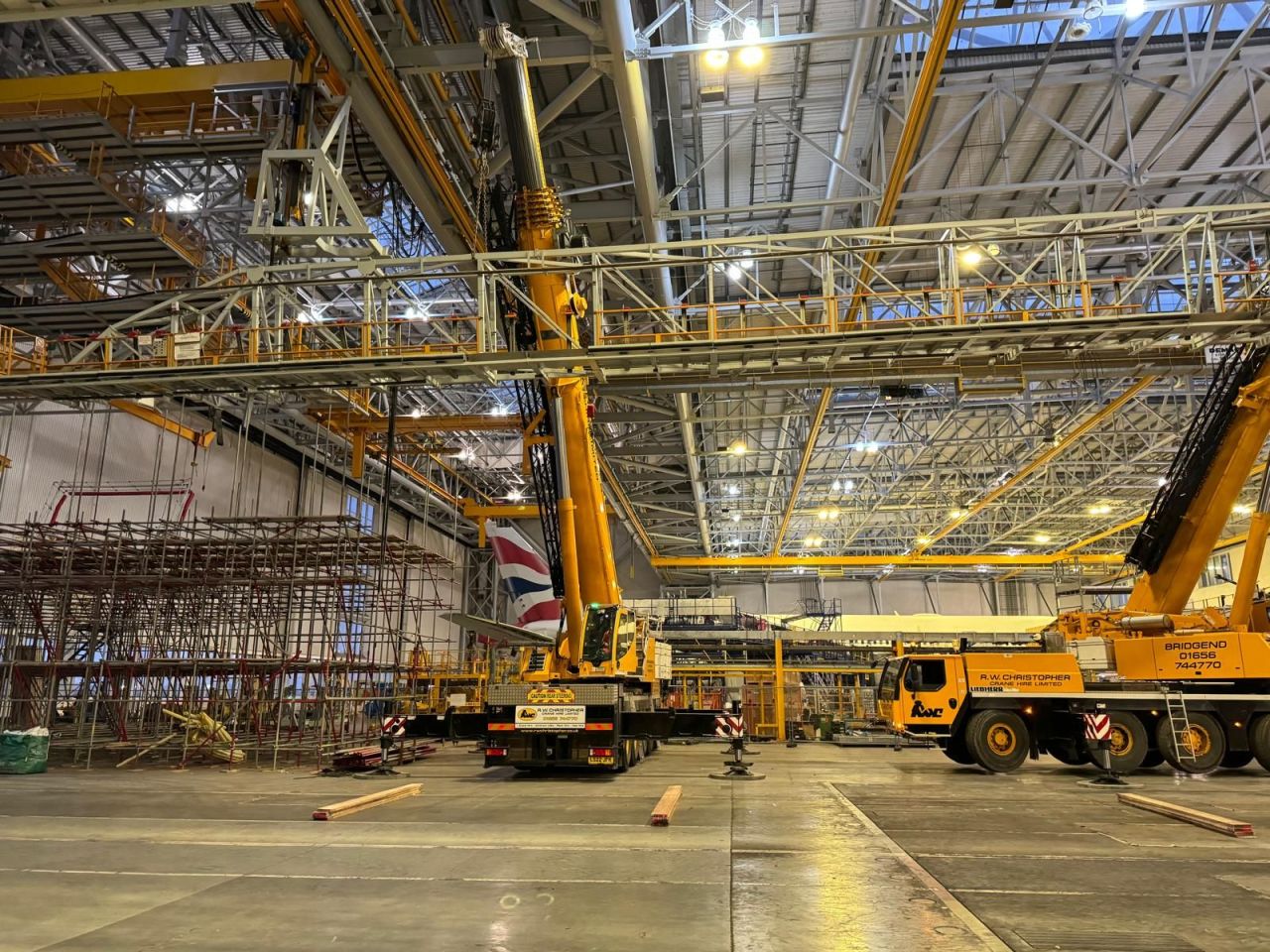

BAEW Bay 3 Hangar Reconfiguration – Removal of Fuselage and Tail Docking

The client is British Airways Property Services (BAPS), with the work taking place at Cardiff International Airport.

Orbis & Reservoir, Staines

Hughes & Salvidge were appointed the role of Principal Contractor for Enabling and Demolition works at the Orbis Buildings, Lovett Ro...

Royal Sussex County Hospital, Brighton

Hughes and Salvidge were appointed the role of subcontractor for demolition works at Royal Sussex County Hospital, Eastern Road, Brighton.

Starlight Point, Heathrow Airport

Hughes and Salvidge were appointed to the role of Subcontractor for the dismantling of the Starlight Point modular office complex at Heat...

Demolition and Dismantle of the Polystyrene Unit - Kingdom of Saudi Arabia

Hughes and Salvidge were appointed Principal Contractor for the demolition and dismantling of S-Chem Polystyrene Production Plant in Al J...

EPC Groupe

Hughes and Salvidge were appointed to the role of Principal Contractor for demolition works at EPC Groupe’s Bramble Island, Essex p...

Print Works, Portsmouth

Hughes and Salvidge commenced the demolition works to the former Print Works in Portsmouth in August 2023. This is a current project for ...