Asbestos Removal

H&S Asbestos is the Asbestos Removal division of Hughes and Salvidge.

Hughes and Salvidge have been undertaking the removal of non-licenced asbestos for decades, and H&S Asbestos expands our ‘complete solution’ by providing the full Asbestos Removal service – licenced and non-licenced – entirely in-house.

Asbestos Removal works carried out by H&S Asbestos are comprehensive and varied.

We regularly undertake the removal of large amounts of Asbestos Containing Materials (ACMs) within multiple locations, on a wide range of sites and environments. All licenced and non-licenced removal works require extremely detailed planning, segregation from others, controlled and enclosed methods of removal, and notifications to the HSE and

relevant authorities

Asbestos Removal Services

- Spray Coatings

- Pipe Insulation

- Boiler Lagging

- Asbestos Insulation Board

- Asbestos cement

- Vinyl Floor Tiles

- Gaskets

- Bitumen Adhesives

- Mastic

- Composites

- Fuses

- Felts

Health and Safety

All Asbestos Removal-related activities are planned, carried out and managed to cause the absolute minimum disruption or concern to any third parties. All access to the site area is controlled by security fencing with appropriate signage and notices posted.

Only asbestos trained and authorised personnel are permitted in the working zones, with no access allowed to any other trades, site staff or members of the public. Our welfare facilities, decontamination units and asbestos waste skips are positioned within these controlled areas for use by H&S Asbestos trained personnel only.

Controlled Conditions

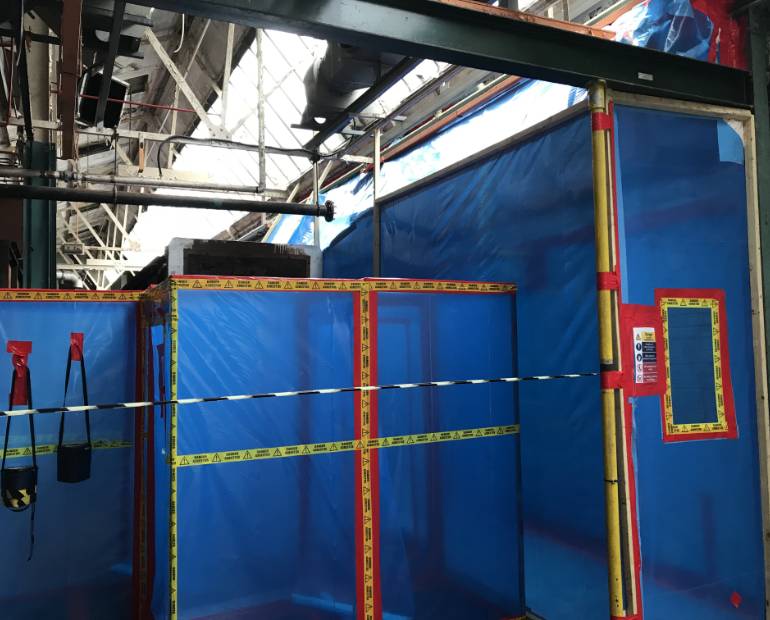

All notifiable/licensable asbestos materials are removed under fully controlled conditions. Working within areas of demarcation and respiratory zones, our teams use the existing matrix of a building, additional timber supports where required, 1000-gauge polythene, adhesive cloth tape, spray adhesive and expanding foam to form fully sealed asbestos working enclosures.

The enclosures are placed under sufficient negative pressure with all access/egress from these enclosures via 3-stage transitional air and bag locks. Large viewing panels and/or CCTV is installed to ensure all areas of the works are visible and able to be inspected and managed accordingly. Each enclosure is subject to a thorough smoke test to ensure sealed and robust containment is in place prior to works commencing.

The removal of the ACM’s within an enclosure is carried out strictly as planned and defined within the item specific plans of work, with all required dust suppression techniques and approved codes of practice followed. On completion of the removal work to each enclosure, a nominated Independent Analyst completes a 4-stage clearance procedure, involving visual inspections, dust disturbance tests and air sampling.

All other non-licenced asbestos materials are removed within controlled respiratory zones by trained and competent Asbestos Removal personnel, wearing the correct RPE/PPE, and using the correct wetting and removal methods. This is overseen by the Site Manager and nominated Independent Analyst.

Our Experience

Hughes and Salvidge is a highly respected name in Demolition, with over 55 years of industry experience. Our Asbestos Removal division, H&S Asbestos, is managed by a qualified and extremely knowledgeable team, with over 45 years of experience

between them.

In Short, H&S Asbestos can be relied upon to safely and successfully plan, implement and deliver small or extensive Asbestos Removal projects, in a timely, cost-effective manner, within high pressure and sensitive environments.

Speak to one of our team

02392 753 733

Contact us for a quote with form below,

Or visit our dedicated site: